Maintenance and Handling of SF6 Circuit Breakers

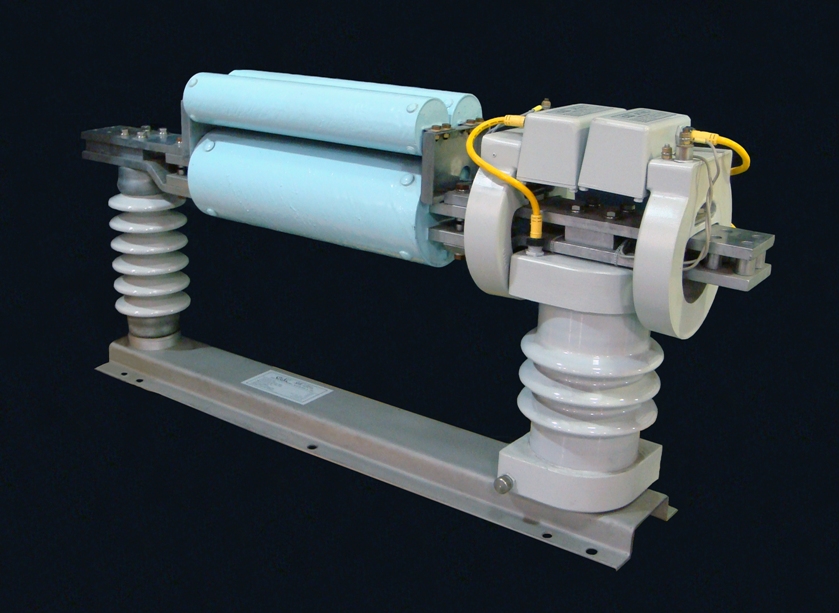

Introduction to SF6 Circuit Breaker Maintenance

Sulfur hexafluoride (SF6) circuit breakers are a critical component in electrical distribution networks, known for their reliability, efficiency, and superior insulating and arc-quenching capabilities. However, the maintenance and handling of SF6 circuit breakers entail complex procedures, especially given the environmental and health concerns associated with SF6 gas.

Key Safety Considerations

- Toxicity: While non-toxic in its pure form, when SF6 is subjected to an electrical arc or high heat in a fault situation, hazardous byproducts can form. These can include hydrofluoric acid and other substances harmful to respiratory and skin health.

- High-Pressure Systems: Internally, SF6 circuit breakers operate with gas under pressure. Sudden release due to accidental damage or equipment failure poses a physical hazard.

- Specialized PPE and Training: Personnel working on SF6 equipment require specific personal protective equipment (PPE) including respiratory protection in certain scenarios. Training must cover safe SF6 handling, arc flash risks, and emergency response in the event of accidental gas release.

Safety Procedures in SF6 Handling

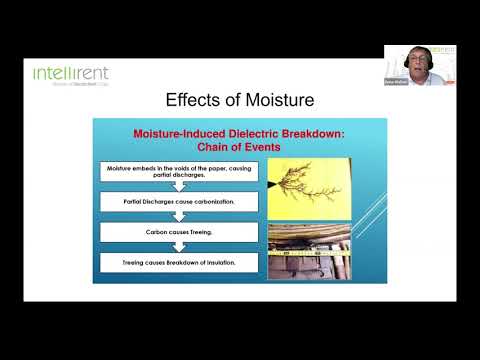

Health and Safety Risks

SF6 gas, while non-toxic, can displace oxygen in the air and lead to asphyxiation if not handled in well-ventilated areas. Moreover, when exposed to...