A Look Inside the Construction and Components of Vacuum Circuit Breakers

Vacuum circuit breakers (VCBs) act as silent guardians within power systems, safeguarding equipment and ensuring grid stability by interrupting current flow during faults. This seemingly simple function relies on a complex and intricate internal construction. This article delves into the essential components and construction principles of VCBs, shedding light on how these technological marvels operate beneath their unassuming exteriors.

The Encasing Vessel

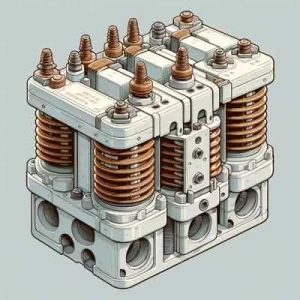

The first line of defense is the outer casing of the VCB. This enclosure, typically made of epoxy resin or porcelain, provides:

- Mechanical Strength: It houses the internal components and safeguards them from external impact and environmental factors.

- Insulation: The material properties provide electrical insulation, preventing current leakage and ensuring safe operation.

- Vacuum Seal: The casing design allows for a robust and leak-proof seal, maintaining the crucial vacuum environment within the breaker.

The Heart of the Breaker: The Interrupter Unit

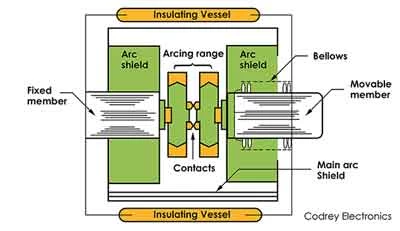

Nestled within the casing lies the core of the VCB - the interrupter unit. This sealed chamber houses the critical components responsible for arc interruption and current flow control:

- Fixed Contact: This stationary contact remains fixed within the unit and serves as the entry point for the incoming current.

- Moving Contact: This movable contact, connected to the operating mechanism, establishes or breaks the electrical connection with the fixed contact, controlling the current flow.

- Arc Shield: This shield surrounds the contacts and aids in containing and directing the arc during the interruption process.

The Key Ingredient: The Vacuum

The true magic of the VCB lies not in its physical components, but rather in the environment they operate within - a high vacuum. This near-perfect vacuum, with extremely low pressure, plays a crucial role in arc interruption:

- Reduced Arc Formation: The low density of particles within the vacuum significantly hinders the formation and sustenance of an arc, minimizing arcing and its associated damage.

- Rapid Arc Quenching: When an arc does form during contact separation, the lack of readily available particles extinguishes it rapidly and efficiently, effectively stopping the flow of current.

Additional Components and Mechanisms

Several additional components contribute to the smooth operation and safety of VCBs:

- Operating Mechanism: This mechanism transmits the control signal to the moving contact, enabling the opening and closing of the breaker contacts. Depending on the type of VCB, this mechanism can be:

- Manually operated: Utilizes a handle for manual control, primarily in low voltage applications.

- Electrically operated: Employs an electric motor or solenoid to control the opening and closing, more common in medium and high voltage applications.

- Bellows: These flexible, airtight connections allow movement of the operating mechanism while maintaining the vacuum seal within the interrupter unit.

- Insulators: Additional insulating materials within the VCB further enhance electrical isolation and prevent internal leakage currents.

Construction Process

The construction of a VCB involves meticulous assembly and stringent quality control procedures:

- Component Preparation: Each component is meticulously cleaned and treated to ensure optimal performance and compatibility within the vacuum environment.

- Assembly: The components are carefully assembled within the interrupter unit, ensuring proper alignment and maintaining a leak-proof seal.

- Vacuum Pumping: The entire interrupter unit is subjected to a rigorous vacuum pumping process, achieving the required high vacuum level.

- Leak Testing: Extensive leak testing is conducted to ensure the integrity of the seal and prevent air from entering the interrupter unit, compromising its functionality.

- Final Assembly: The interrupter unit is then integrated with the outer casing, operating mechanism, and any additional components to form the complete VCB.

VCBs are marvels of engineering, seamlessly combining robust construction with intricate components to achieve efficient arc interruption and reliable current control. Understanding the key components and construction principles of VCBs is crucial for appreciating their functionality and selecting the appropriate breaker for diverse applications in modern power systems.