Calculating the True Cost of Arc Flash PPE Programs

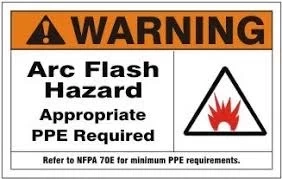

Arc flash Personal Protective Equipment (PPE) programs are vital for ensuring the safety of workers in electrical environments. However, the financial commitment extends beyond the initial purchase of PPE. Understanding and calculating the true cost of these programs is crucial for effective budgeting and safety management.

Visit Our Arc Flash Study Course

Breakdown of Arc Flash PPE Expenses

- Initial Procurement: This involves the purchase of arc-rated clothing, hoods, gloves, and other necessary PPE items. The cost per worker can vary significantly depending on the required arc flash rating, garment complexity, and chosen brands.

- Replacement: Arc flash PPE has a finite lifespan. Exposure to wear and tear, UV light, and repeated laundering degrade its protective properties over time. Replacement schedules should adhere to manufacturer recommendations.

- Storage and Maintenance: Establishing secure storage to protect PPE from damage is essential. Costs include regular inspections for wear, tears, or missing components. Professional laundering, if required, may be an additional expense.

- Worker Training: Thorough training encompasses initial instruction, refreshers, and updates when procedures change. This covers proper PPE donning and doffing, inspection, care, and understanding of its limitations.

- Administrative Overhead: Dedicating staff time to manage the PPE program, maintain records of training and inspections, and handle procurement factors into the overall cost equation.

Initial PPE Procurement Costs

The first step in implementing an arc flash PPE program is the procurement of the necessary equipment.

Quality and Compliance

Investing in high-quality, compliant PPE may have a higher initial cost but is crucial for ensuring adequate protection against arc flash hazards. The selection of PPE should be based on compliance with safety standards like NFPA 70E and the specific needs of the electrical tasks being performed.

Volume and Diversity

The cost will also vary depending on the number of workers needing protection and the range of PPE types required to cover different levels of arc flash risk.

Ongoing Costs in PPE Management

Maintenance and Care

Proper maintenance of PPE is essential to ensure its effectiveness and longevity. Regular cleaning, inspection, and repair of PPE can incur additional costs but are necessary to maintain its protective qualities.

Replacement and Upgrading

PPE components have a limited lifespan and need to be replaced periodically to ensure continuous protection. The costs of replacing worn-out or outdated PPE should be factored into the overall budget. Technological advancements may also necessitate upgrades to more effective or comfortable PPE solutions.

Training and Education Expenses

Training workers on the correct use, maintenance, and inspection of arc flash PPE is critical for ensuring safety and compliance.

Development and Delivery of Training Programs

The creation and implementation of comprehensive training programs represent a significant investment. This includes the cost of developing materials, hiring trainers, and allocating time for workers to participate in training sessions.

Ongoing Training Needs

Training is not a one-time event; refresher courses and updates are needed to keep pace with changes in safety standards and PPE technology, adding to the overall cost.

Inspection and Compliance Costs

Regular inspections and audits of PPE programs are necessary to ensure ongoing compliance with safety regulations.

Internal Inspections

Internal inspections involve costs related to personnel time and resources to conduct thorough reviews of the PPE program and its implementation.

External Compliance Audits

External audits may be required to verify compliance with industry standards and regulations, incurring costs for auditor fees and potential system updates based on audit findings.

Framework for Budgeting Arc Flash PPE Programs

To effectively budget for an arc flash PPE program, organizations need a comprehensive framework that includes all aspects of PPE management.

Total Cost of Ownership

Calculating the total cost of ownership for PPE involves considering initial procurement, maintenance, training, replacement, and compliance costs over the expected lifespan of the equipment.

Predictive Budgeting

Organizations should use predictive budgeting to anticipate future costs related to PPE replacement and upgrades, training needs, and compliance changes, allowing for more accurate financial planning.

Conclusion

The true cost of arc flash PPE programs encompasses a wide range of financial considerations beyond the initial purchase of equipment. By understanding and planning for these costs, organizations can ensure that their arc flash PPE programs are not only effective in protecting workers but also financially sustainable. Comprehensive budgeting and cost management are essential for maintaining the balance between safety compliance and fiscal responsibility.