Hidden Benefits of PPE Audits

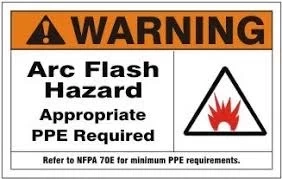

Personal Protective Equipment (PPE) audits and inspections are vital components of a comprehensive safety program, particularly in environments with arc flash hazards. These checks go beyond ensuring that PPE meets regulatory compliance; they play a crucial role in maintaining the integrity and effectiveness of the safety gear.

Regular inspection and auditing of arc flash personal protective equipment (PPE) might seem like another administrative task. However, a well-structured program is critical to ensure PPE serves its intended purpose; protecting workers when all else fails. Meticulous inspections achieve far more than just checking a compliance box.

Visit Our Arc Flash Study Course

Identifying Wear and Tear

- Compromised Protection: Arc-rated fabrics degrade with time and exposure. UV light, improper cleaning, or abrasion can reduce their protective capabilities without visible signs. Inspections identify issues before they become a safety hazard.

- Missing Components: Buttons snap off, seams come loose, and fasteners weaken. Even small defects make PPE less likely to stay closed during an arc flash, reducing its effectiveness.

- Fit Degradation: Repeated use can stretch or compact arc-rated gear. Loose-fitting PPE leaves gaps, compromising protection and increasing the possibility of snag hazards.

Uncovering Worker Misconceptions

- Improper Layering: Some workers might add non-arc-rated clothing under PPE, believing it increases protection. Audits provide an opportunity to educate about the dangers of flammable undergarments.

- "Good Enough" Attitude: Inspections can reveal improperly fastened buttons, rolled-up sleeves, or open hoods. These compromise protection and need to be addressed through retraining.

- Incomplete Understanding: Audits offer a chance to discuss the limitations of PPE, underscoring why it should be used as the last line of defense.

Ensuring PPE Integrity and Performance

Identifying Worn or Damaged Gear

Routine PPE checks help identify worn or damaged gear that might compromise the user’s safety. Over time, even the highest-quality PPE can degrade due to regular use, exposure to harsh conditions, or improper storage. Regular inspections ensure that damaged or worn-out equipment is identified and replaced before it fails during a critical moment, thus preventing potential injuries.

Maintaining Protective Qualities

PPE for arc flash protection, such as flame-resistant clothing, insulated gloves, and face shields, must maintain specific protective qualities to be effective. Regular audits verify that these items continue to provide the necessary level of protection against the thermal and blast effects of arc flashes.

Spotting Worker Misunderstandings

Correcting Improper Use

Inspections provide opportunities to observe how PPE is used in practice, revealing any misunderstandings or incorrect practices among workers. These observations can lead to targeted training or retraining to correct misconceptions and ensure that everyone knows how to use PPE correctly.

Enhancing Safety Training

By identifying common usage errors during PPE audits, safety managers can adapt training programs to address these specific issues. This tailored training approach makes safety instruction more relevant and effective, leading to better compliance and safer work practices.

The Role of PPE Audits in Safety Culture

Promoting a Safety-First Mentality

Regular PPE audits and inspections reinforce the importance of safety in the workplace. They signal to employees that the organization prioritizes their well-being and is proactive about maintaining safety standards.

Building Trust and Compliance

When workers see that their employer is committed to ensuring the functionality and integrity of safety gear, it builds trust. This trust, in turn, fosters a stronger safety culture where individuals are more likely to comply with safety protocols and use PPE properly.

Technological Advancements in PPE Inspections

Utilizing Digital Tools for PPE Management

The integration of technology into PPE management, such as the use of digital tracking systems and mobile apps, can streamline the audit and inspection process. These tools can provide real-time data on PPE usage, maintenance schedules, and replacement needs, enhancing the efficiency and accuracy of PPE programs.

Incorporating Smart PPE

Advancements in smart PPE, equipped with sensors and connectivity, allow for continuous monitoring of the condition and usage of safety gear. This technology can automatically alert safety managers to issues with PPE, further improving the effectiveness of inspection programs.

Conclusion

PPE audits and inspections are crucial for maintaining the safety and effectiveness of arc flash protective gear. These processes not only ensure that PPE is in good working condition but also identify and correct worker misunderstandings, contributing to safer work practices. By integrating regular PPE checks into the safety program, organizations can foster a culture of safety, ensure compliance with standards, and protect their workers from the dangers of arc flash incidents. Investing in technology and training enhances these benefits, making PPE audits a key element in effective safety management.