Overload Relays for Motor Protection

Improve system reliability and efficiency

BY KEVIN TRIMMER, Eaton Corporation

Nearly a third of global energy demand is attributable to manufacturing. Overall, the industry’s use of energy has grown by 61 percent between 1971 and 2004. According to the International Energy Agency (IEA) analysis, there are substantial opportunities to improve worldwide energy efficiencies.

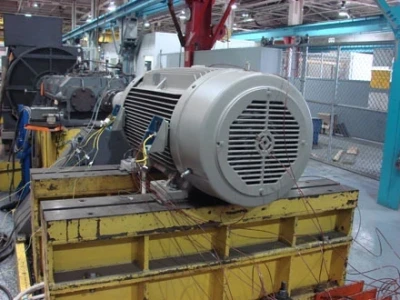

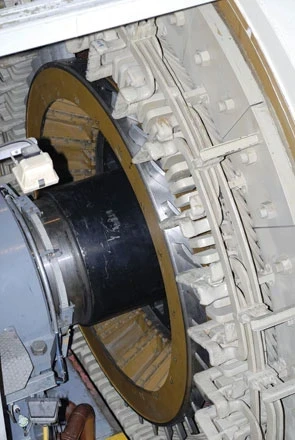

More specifically, motor systems use more than 75 percent of a plant’s electricity. Driving energy efficiencies is more than being green. It makes good business sense, and delivers improved system productivity, increased reliability, and reduced energy and maintenance costs. As energy becomes more difficult and costly to find, refine and use, it is critical to understand available methods of motor control and protection.

Nearly every motor in an industrial facility uses some form of protection. Selecting the appropriate motor control can help to optimize maintenance operations and reduce energy costs.

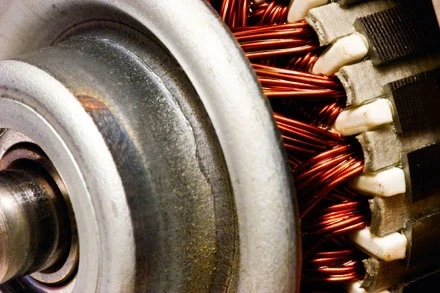

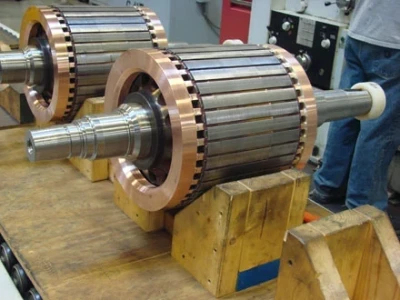

ADVANCING MOTOR PROTECTION

Standard overload protection has evolved beyond strictly monitoring current for an overload condition. Today’s electronic overload relays for motor protection are capable of monitoring power, power factor, current and voltage, while continuously providing this data through standard industry protocols.

There is a wide array of motor control and protection solutions available. The challenge is determining what level of motor protection is required for a specific application. To find an appropriate solution, it is important to first understand the various failure modes within an industrial facility and the impact that each can have on uptime and throughput.