Advances and Limitations in Arc Flash Safety

Remote operation technologies, such as remote racking, diagnostic, and equipment control solutions, have become pivotal in enhancing arc flash safety in electrical systems. These innovations allow personnel to operate and monitor electrical equipment from a safe distance, reducing the risk of arc flash exposure.

The ability to operate, diagnose, and control electrical equipment from a safe distance represents a significant step forward for worker safety. Remote racking systems, diagnostic tools, and monitoring solutions are seeing increased adoption, but it's important to have a realistic understanding of their capabilities and limitations.

Visit Our Arc Flash Study Course

How Remote Operation Reduces Risk

- Removing Personnel from the Arc Flash Boundary: The core benefit is creating physical distance between workers and energized equipment during tasks that carry inherent risks.

- Reduced Live Work: Remote racking eliminates the need for energized work in many routine switching operations.

- Real-time Diagnostics: Remote monitoring of current, voltage, and temperature can provide early warnings of potential problems, enabling proactive intervention.

Types of Systems

- Remote Racking: Electromechanical or robotic devices that enable the insertion and removal of circuit breakers or other switchgear components from a safe distance.

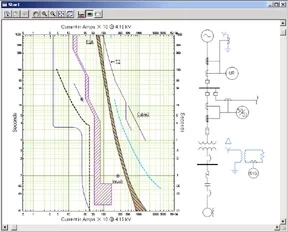

- Remote Monitoring and Diagnostics: Networks of sensors within equipment, relaying data in real-time to dashboards and analytics platforms.

- Remote Equipment Control: The ability to open or close switches, adjust settings, or even perform equipment resets remotely.

Advances in Remote Operation Technologies

Remote Racking Systems

Remote racking systems enable the insertion and removal of circuit breakers from a control panel located at a safe distance. This process minimizes the need for direct contact with the switchgear, significantly reducing the risk of arc flash incidents during racking operations.

Diagnostic and Monitoring Tools

Advanced diagnostic tools and monitoring systems provide real-time data on the condition and performance of electrical equipment. These systems can detect early signs of equipment failure or degradation that could lead to an arc flash, allowing for preventative maintenance and timely interventions.

Automated Control Systems

Automation in electrical systems has led to the development of sophisticated control solutions that can operate equipment remotely. These systems enhance safety by allowing operators to execute potentially hazardous operations from a secure location, away from the direct risk of arc flash.

Potential Limitations and Remaining Hazards

Reliance on Technology and Infrastructure

While remote operation technologies offer significant safety advantages, they also introduce dependencies on the underlying technology and infrastructure. Failures in software, hardware, or communication networks can impact the reliability of these systems and potentially reintroduce risks.

Training and Competency

Effective use of remote operation technologies requires specialized training and competency. Operators must be proficient in using the systems and understanding their limitations. Inadequate training can lead to operational errors, potentially compromising safety.

Complacency and Overreliance

There is a risk of complacency or overreliance on technology, where the human element of safety vigilance may diminish. It’s crucial to maintain a high level of safety awareness and not become overly dependent on remote operation technologies to manage all aspects of arc flash risks.

Integrating Remote Operation with Comprehensive Safety Strategies

Part of a Layered Safety Approach

Remote operation technologies should be integrated as part of a layered safety approach, complementing other arc flash safety measures such as PPE, maintenance practices, and safety training. This holistic approach ensures that safety is not solely dependent on any single measure or technology.

Continuous System Evaluation and Upgrades

Ongoing evaluation and upgrading of remote operation systems are necessary to keep pace with technological advancements and evolving safety standards. Regular system checks, updates, and upgrades help maintain operational effectiveness and safety integrity.

Collaboration and Continuous Learning

Collaboration between safety professionals, engineers, and operators is essential to maximize the benefits of remote operation technologies. Sharing experiences and knowledge can lead to continuous learning and improvement in arc flash safety practices.

Conclusion

Remote operation technologies offer significant advances in arc flash safety, reducing the need for direct interaction with potentially hazardous electrical equipment. However, these technologies are not without limitations and should not be seen as a panacea for arc flash risks. Effective implementation requires careful consideration of the systems’ capabilities, limitations, and integration into broader safety and operational frameworks. By understanding and addressing these challenges, organizations can leverage remote operation technologies to enhance safety while maintaining robust operational performance.