Home Building Automation

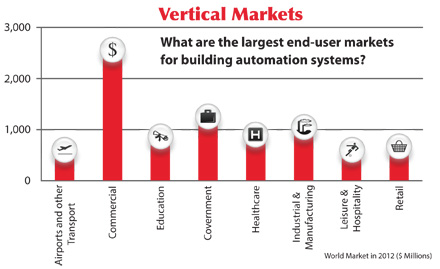

Building Automation

Building Automation

2015 Intelligent Lighting Review

Lighting is a load which every facility manager and operator must consider from an energy and maintenance perspective. In most commercial buildings, lighting is...

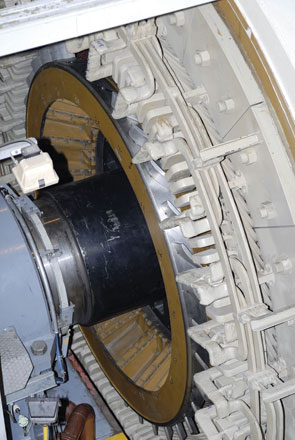

Electrical Safety

Absence of Voltage Testing – An Update on Accepted Approaches

Absence of voltage testing is a vital step in the process of verifying and establishing a de-energized state of any electrical system....

© 2017 Intelligent Power Today Magazine. All Rights Reserved.